Tappan Zee

Hudson River, New York | United States

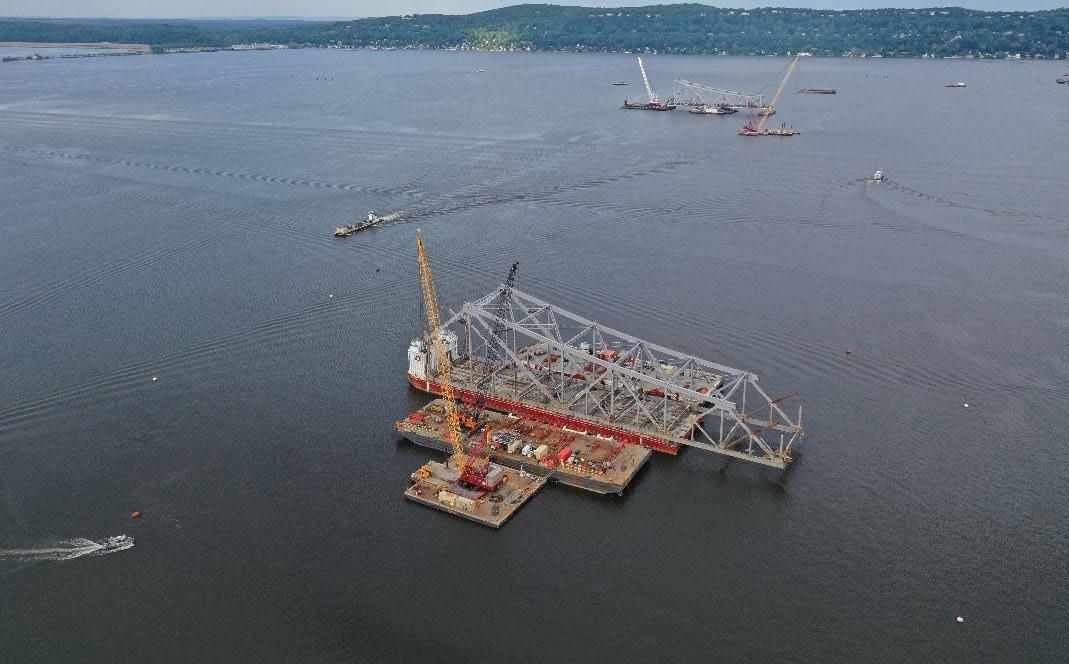

After the successful emergency demolition, Resolve Marine was contracted to remove the span structure in its entirety from the Hudson River. The company mobilized two 300-feet x 100-feet US flagged Jones Act compliant deck barges outfitting them with 20 chain pullers, an arrangement capable of lifting up to 6,000 tons. Working through icy winter conditions, Resolve Marine prepared the structure for lifting. This required the manual trimming of approximately 1,500 tons of twisted steel from the span to free the structure from the bridge caissons at either end. Once prepared, Resolve Marine connected the pullers to the lift rigging and with the application of 4,500 tons of lift, pulled the structure from the riverbed to the surface.

Once debris was removed from underneath the structure, the bridge span was shifted south and rotated 90 degrees. This maneuver took careful coordination from multiple vessels and was synchronized during fast-moving tidal currents. The span was then loaded onto the semi-submersible lift barge and then towed for processing as scrap steel.